A domestic wastewater treatment plant for 5-7 persons will allow to achieve a high standard of water quality in family houses. Easy installation and simple maintenance of the purifier ensures maximum convenience and efficiency.

Wastewater treatment plant for 5-7 persons DČB 5K (EKOL 0,5) is an ideal choice for treatment of sewage water from buildings that cannot be connected to the existing sewage system due to their location or other reasons. It is also a suitable solution for situations where no adequate sewage system has been built yet.

Description and function of the DČB 5K (EKOL 0,5) sewage treatment plant

DČB 5K consists of an IPP tank. All parts of the tank except the biorotor shaft, bearings and drive are made of integral polypropylene. The tank is enclosed by a cover made of UV-resistant polypropylene plates. The cover is not permeable.

In the plastic tank, the partitions or bore walls create sub-functional spaces for:

- separation of light and floating substances

- settling of suspended matter

- digestion (anaerobic sludge stabilisation)

- separation of sludge flakes from the treated water

How the DČB 5K wastewater treatment plant works

The technology of wastewater treatment is based on an aerobic process, where organic substances are removed by the activity of microorganisms (synthesis and multiplication of aerobic bacteria) in the presence of air oxygen.

The DČB 5K domestic sewage treatment plant provides aerobic wastewater treatment, which has the advantage of low acquisition costs, easy operation and stability of operation. It is thus the perfect choice for permanently occupied buildings such as family houses or even larger buildings, namely hotels and other large holiday resorts.

The microbial colonisation that grows on the rugged surface of the biocontactor results in a gradual reduction of the organic matter content and a reduction of the nitrogen content. When the machinery is taken out of operation, the treatment process is carried out as in a septic tank and there is no need for a drain.

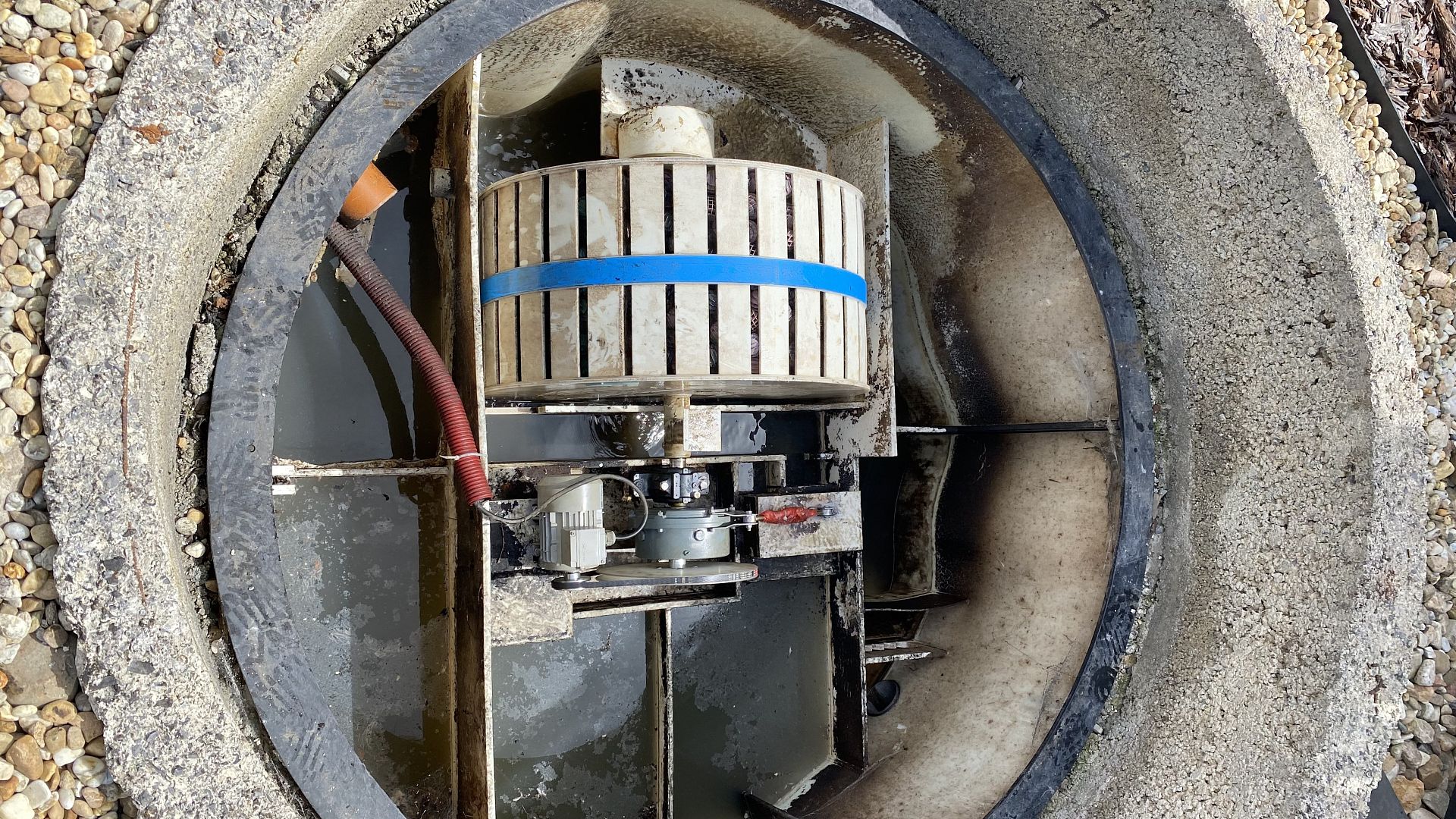

The treated water flows into the plant from the sewer through the inlet to the settling tank, where both light and floating substances are separated and the coarse substances and impurities that are collected in the settling tank are removed. Next, the water flows into the biozone area where the biocontactor rotates.

The biocontactor is cage-type and the carrier of the sessile microorganisms is small plastic elements. In the biozone, the water is purified by the action of the micro-organisms. A pumping device continuously draws water from the storage space into the bio-zone space, ensuring a constant storage volume of at least 400 litres. Thebiorotor also includes a conveyor belt that returns the sludge from the biozone back to the settling tank. The treated water flows through the hollow centre of the biorotor via a degassing trough into the settling tank. The amount of water flowing out can be controlled by an adjustable overflow. The settled sludge is flushed out of the settling tank through a drainage shaft back into the bio-zone. The treated water flows out of the settling tank through the outlet spout.

Use of the DČB 5K wastewater treatment plant

Similarly to the DČB 4K domestic sewage treatment plant for 2-4 persons, the DČB 5K is used to treat sewage from housing facilities, residential sites, farms, recreational facilities with 5-7 equivalent inhabitants (for 1 EO a BOD5 value of 60 g/day and a wastewater volume of 150 l/day are considered). The initial basis for the design and location of WWTP 5 K are the requirements of investors, planning authorities and water management authorities.

Technical data of the DČB 5K (EKOL 0,5)

| Parameter | DČB 5K |

| Basic dimensions [mm] | 2 000 x 1 900 |

| Weight [kg] | 350 |

| Biorotor drive by electric motor | 120W/400V |

| Qd [m3/d] | 1m3 |

| Height of inflow | 1 260 mm |

| Outlet height | 1 130 mm |

The inlet for connection to the sewerage system is made with a polypropylene pipe with a diameter of 160/150 mm, the outlet with a polypropylene pipe with a diameter of 110/90, or according to the customer's requirements. For the proper functioning of the WWTP, it is necessary to design the WWTP with respect to the maximum flow and total daily load as well as with respect to the BOD5 concentration limit of 400 mg/l. For higher concentrations, the design of the WWTP should be discussed with the manufacturer. The WWTP achieves a BOD5 effluent value of up to 25 mg/l at maximum hydraulic and metabolic load.

Base concrete slab O 2 600 mm, thickness according to the bearing capacity of the ground. Flatness of the slab ± 5 mm. Inlet pipe 160/150, inlet axis 1365 mm above base, outlet pipe 110/90.